DGMF Mold Clamps Co., Ltd is a leading mould clamp manufacturer and mold clamp supplier in China.

For 10 Years, We Have Been Manufacturing Mold Clamps

99% of customers are very to cooperate with Hualida Tools.

More than 98.5% customers praise our mold clamp products.

Over 95% of our customers return to choose our mold clamps and recommend us.

About DGMF Mold Clamps

Mold Clamps Supplier

DGMF Mold Clamps Co., Ltd is a leading mold clamps supplier.

Mould Clamps Manufacturer

DGMF Mold Clamps Co., Ltd is a professional mould clamps manufacturer.

Large Storage

DGMF Mold Clamps Co., Ltd has a large storage of mold clamps, bolts, nuts, and washers.

who we are

Mould Clamp Manufacturer

Wide Selection

DGMF Mold Clamps manufacturer carries a wide range selection of mold clamps catering to different applications and professional requirements.

Fast Delivery

All mold clamps are available in stock and supported by a fast delivery service. This is to not cause delay to existing projects of the clients.

Durable Materials

DGMF Mold Clamps Co., Ltd uses high-quality and durable materials in producing every single mold clamp component. This is to provide you with powerful mold clamps that will live on the job site.

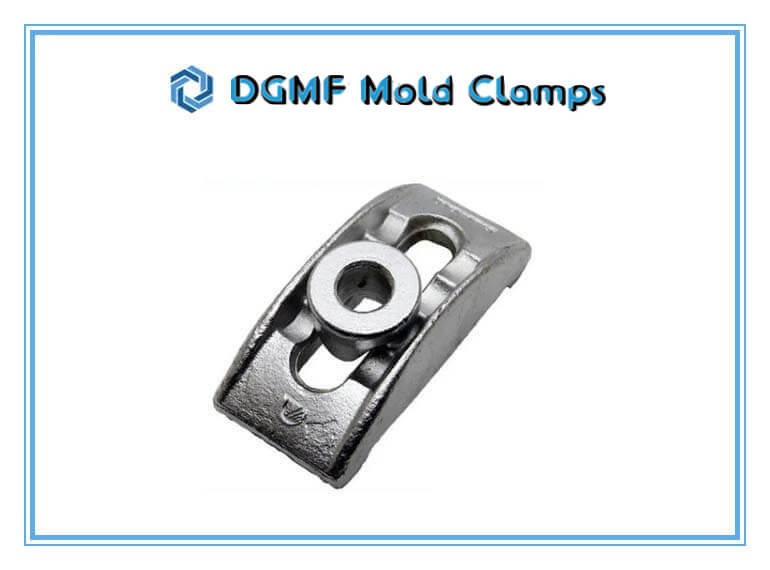

Quick Change Mold Clamp

Quick-change mold clamp is typically used for injection molding

Forged Mold Clamp

Forged Mold Clamp is typically used for injection molding & die-stamping.

Clamp for mold

The forged clamp for mold clamping is typically used for CNC milling & die-stamping machines.

Mould Clamp Manufacturer & Mold Clamp Supplier

DGMF Mold Clamps Co., Ltd is a professional mould clamp manufacturer and mold clamp supplier in China.

DGMF Mold Clamps Co., Ltd supplies all the mold clamps specifications, including M10, M12, M14, M16, M18, M20, M22, M24, M30, M36, etc.

The mold clamp types include closed-end, open-end, strapped, stepped, quick-change, forged, hardened, and high-quality precision mold clamps.

Featured mold clamps

The T Bolt Mold Clamp Assembly Set includes the following:

1 PC Quick-change Mold Clamp

1 PC T Bolt

1 PC Flange Nut

The Forged Mold Clamp For Injection Molding Assembly Set includes the following:

1 PC Forged Injection Mold Clamp

1 PC T Bolt

1 PC Flange Nut

The universal mold clamp Assembly Set includes the following:

1 PC Universal Mold Clamp

1 PC T Bolt

1PC Flange Nut

The universal mold clamp Assembly Set includes the following:

1 PC Step Block

1PC Strap Clamp

1 PC T Bolt

1PC Flange Nut

What Our customers say

I've worked with DGMF Mold Clamps for more than 5 years, their mold clamps are very durable.

Lizzie Thompson

I was introduced to DGMF Mold Clamps many years ago, and I buy mold clamps from then on.

Emma Velasquez

Advantages

Large Storage

- 4 big warehouse of mold clamps storages

- Full range of mold clamps styles and specifications available

Direct Manufacturer

- Factory direct mold clamp pricing

- Next day shipment

- Custom mold clamp service available

Pick the below mold clamp types that best fit your machines. All mold clamps are available in stock. If you cannot find the suitable one, contact us!

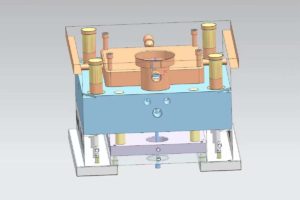

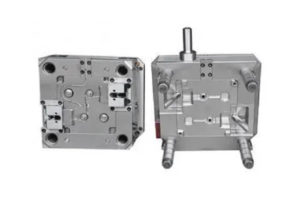

Mold Clamps For Injection Molding

Mold Clamps And Mounts

Quick Mold Clamps

Mold Clamps Injection Molding

Mold Clamp Assembly

Arching Mold Clamps

Mold Clamp Bolts

Quick Mold Change Clamps

Mold Clamp For Jewelry

Injection Mold Clamp Factor For Pp

Mold Clamp Injection Moulding

Mold Clamp Misumi

Mold Mounting Clamps

Plastic Mold Clamp Manufacturer

Machined Mold Clamps

Mold Clamp Washer

Injection Mold Clamps

Injection Mold Toe Clamps

Clamp Mold

Clamp Lock Mold

Mold Toe Clamps

Metric Mold Clamps

Mold Clamp M16

Mold Handle Clamp

Forged Mold Clamps

Mold Clamp Injection Molding

Magnetic Mold Clamp

Plastic Mold Clamp

Rubber Mold Clamp

Zhushi Mold Clamps

Zhushi Mould Clamps

Plastic Injection Mold Clamps

Mold Clamping Unit

A Mold Clamp

Mold Cutting Clamp

Injection Mold Clamp

Quick Mold Clamp

Mold Clamps Adjustable

Mold Clamps Holding Weight

Mold Clamps For Steel Molding

Mold Clamps For Injection Molding Crab

Mold Clamps For Holding

Molds To Platens

Mold Clamps Near Me

Mold Clamps Supplier Near Me

Mold Clamps Manufacturer Near Me

Mold Clamps Store Near Me

Matex Mold Clamps

Manual Mold Clamps

Magnetic Mold Clamps

Dme Machine Mold Clamps

Injection Molding Mold Clamps

Punch Mold Clamps

Ppe Mold Clamps

Mold Clamps Dme

Tapped Clamp Strap

Clamp Strap Assemblies

Adjustable Strap Clamp

Plastic Injection Mold Clamps

Parting Line Mold Clamps

Mold Clamp Rectangular Washers

7/16 T Slot Clamping Kit

5 8 T Slot Clamp Set

58 Pc Steel Clamping Kit

58pc Deluxe Steel Clamping Kit

Mold Smart Clamp

Forged Tapped End Mold Clamp

Stepped Strap Clamps

Strap Clamps

Tapped End Mold Clamp

U-clamp For Injection Molding

U-shaped Mold Clamp

Machined Mold Clamps

Machined Closed Toe Clamp

Machined Open Toe Clamp

Injection Molding Clamps

Mold Clamps T Bolt

Setup Mold Clamps

Setup Clamps

Low-profile Clamps

Low-profile Setup Clamps

Step Setup Clamps

Step Setup Mold Clamps

Setup Clamp Supports

Side Clamps

Milling Machine Clamps

Milling Machine Mold Clamps

Milling Machine Clamp Kits

Machinist Clamp Kits

Step Block Mold Clamp Kit

Step Block Clamp Kit

Step Blocks

Single Toe Clamp

Plain Clamps

Tapped End U-clamp

Stepped End Clamps

Serrated End Clamp

Step Clamps

Forged Plain Clamps

Forged Tapped Plain Clamps

Forged U Clamps

Forged Finger-tip Clamps

Forged Gooseneck Clamps

Heavy-Duty Mold Clamps

Clamp For Fixing Mold

Mold Clamp Forged

Forged Mould Clamp

Milling Clamps

Forged Tapped Plain Mold Clamp

Forged Quick Mold Clamp

Forged Quick Arching Clamp

Forged Arching Clamp

Die Clamps

Standard Die Clamp

Open Toe Die Clamp

Forged U Clamp

Forged Gooseneck Clamp

Quick Change Arching Mold Clamps

Mold Press Clamp

Mold Clamp With Adjustable

Support Bolt

Strap Mold Clamp

Strap Mould Clamp

T-slotted Mold Clamp

Injection Molding Machine Clamps

Press Tool Clamp

Mold Clamp With T Slot Bolt

Toyo Mold Clamps

Small Mold Clamps

Ejection Mold Clamps

Injection Mold Clamps For Sale

Closed Slot Mold Clamps

Closed Slot-style Mold Clamps

Open Slot Mold Clamps

Open Slot Style Mold Clamps

Easy Mold Clamps

Easy Clamps

Open Toe Mold Clamps

Open Toe Style Mold Clamps

Closed Toe Mold Clamps

Closed Toe Style Mold Clamps

Clamping Elements

Press Strap Clamps

U-type Mold Clamps

T-slot Clamps

Strap Clamps

C Washer

Tapped End Clamps

Tapped End Mold Clamps

Tapped End Mould Clamps

For T Slot Machine Clamps

For T Slotted Machine Clamps

Quick-change Mold Clamps

High-speed Mold Clamps

Quick Change Mould Clamps

High-Speed Mould Clamps

Quick Mold Clamps

Quick Mould Clamps

High-Speed Quick-change

Mold Clamps

Heavy-duty Quick-change

Mold Clamps

Din 6314 Steel Plain Clamps

Din 6314 Clamps

Plain Clamp Din 6314

Simple Clamp Din 6314

Clamp Straps Din 6314

Din 6314 Straight Clamp

Din 6314 Mechanical Clamping

Clamps Din 6314

Clamp Flat Din 6314

Plain Clamps Din 6314

Din 6314 Plain Clamps

Closed Toe Plain Clamps

Molding Clamps

Clamp Mold

U Mold Clamps For Injection Molding

Step Clamp Set

Mold Die Clamps For Injection Molding

58pc Clamping Kit

T Slot Quick Clamp

T Slot Toe Clamps

T Slot Nuts

T-slot Clamping

Tapped T-nuts

Flange Nuts

Hex Nuts

T Slot Nuts

Clamping Stud Hex Spanner Bolts

Swivel Levelling Bolt

Rectangle Washer For Mold Clamp

Mold Clamp Washers

No-twist Rectangular Mold Washer

No Turn Washer

Extension Nuts

Hold Clamps

BUY MOLD CLAMPS

Contact DGMF Mold Clamps Company NOW!

-

Quick Change Mold Clamp

Read more -

Forged Mold Clamp

Read more -

Forged Uni Clamp for Mold

Read more -

Step Block Mold Clamps

Read more -

Heavy-duty Step Blocks

Read more -

Forged Smart Clamp for mold clamping

Read more -

Hardened Universal Mould Clamp

Read more -

Forged Uni Mold Clamp Set

Read more -

Heavy-duty Universal Mold Clamp Set

Read more -

High-quality T Bolt Mold Clamp Set

Read more -

Heavy-duty T Bolt

Read more -

Heavy-duty Mold Clamping Stud With A Spanner

Read more -

Heavy-duty Flange Nut

Read more -

High Strength T Slot Bolts

Read more -

Heavy-duty Mold Clamp Washers

Read more -

Heavy Hex Nut

Read more

Best Mold Clamp Price Quote Now

Have your questions about DGMF Mold Clamps Co., Ltd? Can’t find the right mold clamps you need? Let our sales team help you with that.

Services

Mold Clamps Supply

DGMF Mold Clamps company provides a wide range of mould clamps for injection moulding, CNC machining, drilling, stamping, etc.

Tools Supply

DGMF Mold Clamps company provides thousands of tools you may need in all industries.

DGMF Mold Clamps Company's New Articles

5 Special Precision Injection Moulding Design Guides

After reading this 5 Special Precision Injection Moulding Design Guides article, you will know 5 important points of precision injection moulding design guidelines. Injection moulding

12 Major Injection Moulding Processes Explained

This 12 Major Injection Moulding Processes Explained article talks about what is injection moulding and the 8 kinds of injection moulding processes processing, advantages, disadvantages,

What Are The Effects of Mold Temperature In Injection Molding?

This article discusses the effect of mold temperature in injection molding in 4 areas: What are the factors that affect the cooling of the injection

What is 45# Steel Material?

What is 45# Steel? 45# steel is generally referred to as 45-grade steel, a high-quality carbon structural steel, characterized by higher strength and resistance to

Stamping Die Design Guidelines, 75 Taboos And Rules

This article describes the Stamping Die Design Guidelines, the taboos of the three main stamping die design processes, namely blanking, bending and drawing, and the

Mechanical Design Steps and 525 Taboos

What is mechanical design? Mechanical design is the design of parts, components, products, or systems of a mechanical nature. For example, mechanical design includes the

5 Factors Affect the Shrinkage of Thermoplastic Molding

What are the factors that affect the shrinkage of thermoplastic molding? The following are 5 factors that affect the shrinkage of thermoplastic molding and the

17 Injection Molding Problems And Solutions

After reading, you will know 17 injection molding problems and solutions. Injection molding problems and Solutions 1. Scrap jumping hole The punch length is not